roof arch curving machine

roof arch curving machine

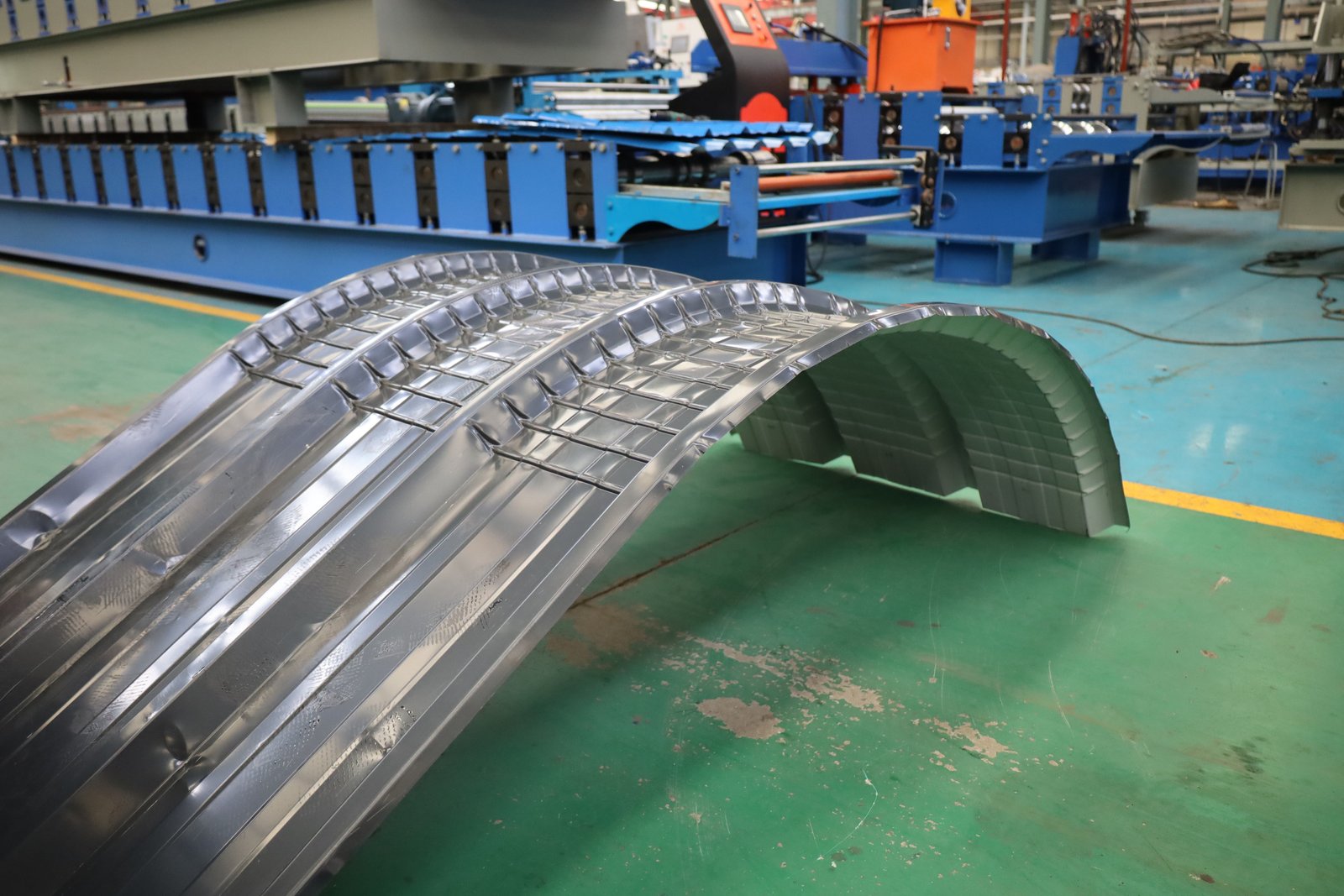

A roof arch curving machine is specialized equipment used in the construction and metalworking industry to curve or bend metal roofing sheets into arch-shaped panels. These machines are specifically designed to create arched or curved roofing components, offering a unique aesthetic and functional solution for various architectural designs.

Key features and functions of a roof arch curving machine include:

Material Handling: The machine is designed to work with metal roofing sheets, typically steel, aluminum, or other durable metals, feeding them into the curving process.

Curving Process: Metal roofing sheets pass through the machine, where they undergo a series of bending or curving operations using rollers, presses, or other forming mechanisms. These components shape the metal sheets into the desired arch or curved profile.

Customization and Flexibility: Some machines offer adjustable settings to create different curvature radii, widths, and lengths, allowing for customization to fit specific architectural designs or project requirements.

Precision and Accuracy: Roof arch curving machines are engineered for accuracy, ensuring uniformity and consistency in the curvature of the formed roofing panels.

High Efficiency: Modern machines operate efficiently, producing curved roofing panels at a relatively fast pace to meet project timelines and demands.

Integration into Roofing Systems: The curved or arched roofing panels produced by these machines are incorporated into roofing systems, offering an aesthetically pleasing and structurally sound solution for architectural design elements.

Roof arch curving machines play a significant role in architectural design, allowing for the creation of unique and visually appealing roof structures. The curved roofing panels produced by these machines not only enhance the aesthetic appeal of buildings but also contribute to the structural integrity and functionality of roofing systems by shedding water efficiently and providing additional strength and support.

Industry-specific attributes

Other attributes

With over 20 years of experience in the roll forming machine industry, our company is widely recognized for providing exceptional quality products and services. Since our establishment in 2011, we have remained steadfast in our commitment to customer satisfaction, consistently striving to exceed their expectations in all aspects of our business.

Our team is comprised of seasoned professionals who are dedicated to delivering innovative solutions that cater to the dynamic needs of our clients. We leverage state-of-the-art technology and equipment to ensure that our products meet the highest quality standards demanded by the industry.